Analysis of the processing characteristics of new materials

Release time:2024-12-11 Click:249Modern manufacturing depends much on sheet metal processing. The development of new metal materials with the ongoing progress of science and technology has presented both possibilities and problems for this discipline. Improving the efficiency and quality of sheet metal processing depends much on in-depth study of the processing properties of these novel materials.

High-strength aluminum alloys and titanium alloy sheets are among the new sheet metal materials with special physical and chemical qualities that vary greatly from those of conventional sheet metal in processing terms. Consider high-strength aluminum alloy sheets for one instance. Popular in aerospace, automotive, and other industries, they offer a high strength-to---weight ratio. This high-strength quality, meantime, also causes certain processing challenges. Its enhanced hardness and strength call for more cutting force and forming pressure during cutting and forming; common processing instruments and molds are prone to wear and breakage. For instance, the tool wears far quicker when processing high-strength aluminum alloy sheets using conventional milling technology than when processing regular steel sheets, which calls for more frequent tool replacements and thereby increases processing expenses and time.

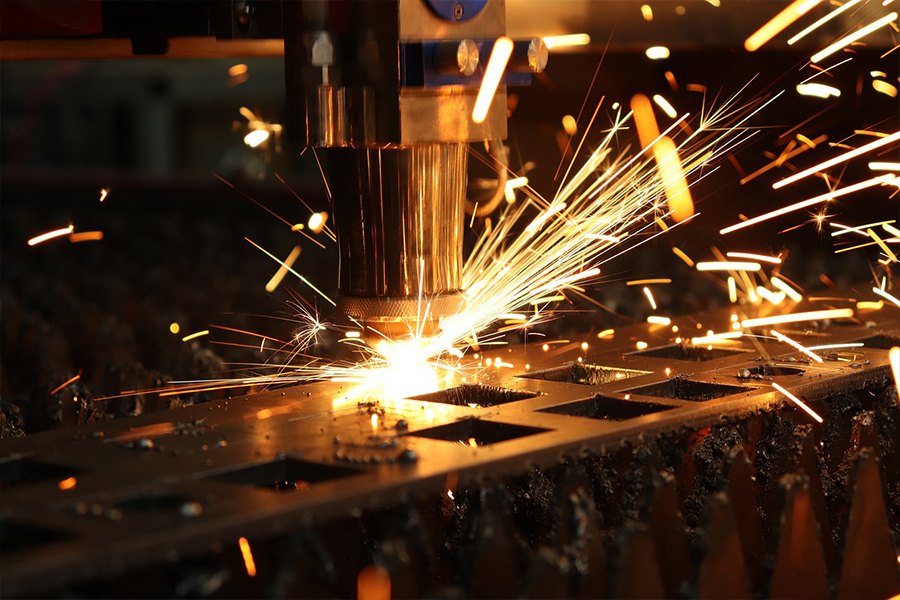

High temperature performance and great corrosion resistance of titanium alloy sheets are well-known. Still, its processing qualities are more complex. Thermal conductivity of titanium alloys is low. Heat is readily accumulated in the cutting region and difficult to disperse during processing, which causes the cutting temperature to rise sharply. Apart from increasing tool wear, excessive temperature will lead to surface burns and microstructural changes in titanium alloy sheets, therefore compromising their mechanical characteristics and surface quality. For instance, if good cooling techniques are neglected while laser cutting titanium alloy sheets, clearly visible heat-affected zones would show on the cutting edges, therefore compromising the material's strength and toughness.

Moreover distinct from conventional materials is the plastic deformation behavior of newly developed metal sheet materials. Some novel alloy sheets exhibit clearly anisotropy and display nonlinear properties during the forming process, with regard to stress-strain curves. This implies more exact control of processing parameters is needed in forming processes like bending and stretching. For instance, the bending angle limit and springback degree in various directions are somewhat varied when bending a new kind of magnesium alloy sheet. It is challenging to get a bent component that satisfies the accuracy criteria if the procedure is conducted using conventional processing expertise.

Furthermore stricter are the surface quality criteria for newly developed metal sheet materials. Even little surface scratches and roughness changes might compromise the performance and service life of the product as they are often utilized in high-end manufacturing sectors like precise components of electronic equipment and medical devices. One of the main difficulties in the processing is preventing damage to the material surface. For instance, the abrasive particle size, jet speed and angle must be precisely changed when processing fresh metal sheets using abrasive jet to remove the material without compromising the surface integrity.

Considering the processing properties of these novel materials, the metal sheet processing sector is also continuously investigating and developing processing techniques and systems. Develop new high-performance tool materials and coatings to increase the wear resistance and heat resistance of tools when processing new materials; use advanced cooling and lubrication technologies, such micro-lubrication and low-temperature cooling, to effectively control the temperature during the processing process; develop intelligent processing equipment that can effectively control the temperature during the processing process;

New metal sheet materials' processing properties have given the metal processing sector several fresh research subjects and pragmatic difficulties. We can fully utilize the benefits of new materials, support the metal sheet processing sector to develop in the direction of greater precision, higher efficiency, and more green and environmentally friendly, and meet the rising demand of modern high-end manufacturing for metal sheet parts only by deeply understanding these characteristics and constantly innovating processing technologies and methods.