Bending process challenges: Precision structure and appearance consistency of inkjet printer chassis

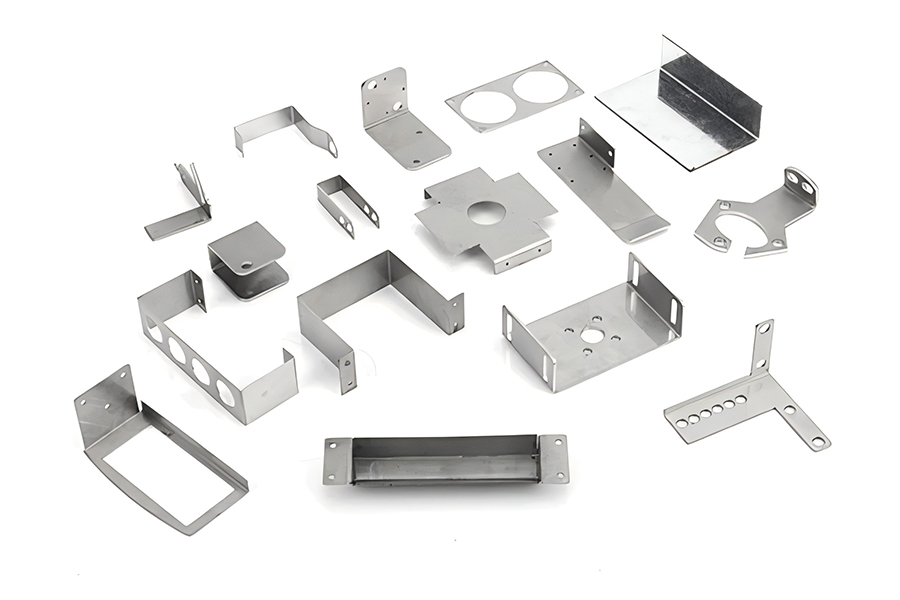

Release time:2024-12-04 Click:105We will present to you in this paper how Chuntian Technology implements lean measures in the bending process to increase the accuracy and strength of the inkjet printer chassis.

Selection of sheet metal material comes first in inkjet printer production.

The initial phase of inkjet printer manufacture is the choice of sheet metal material, which is absolutely vital for the quality of the output. Plasticity and strength qualities of various materials vary. Usually selecting corrosion-resistant and high-strength stainless steel, the shell of the inkjet printer is mostly utilized to protect the internal electrical components and ink system to fit the operation of the equipment in various working situations. Chuntian Technology values quality control on every product highly. From rigorous physical testing to chemical performance testing, we tightly regulate every connection to guarantee that the components utilized can totally satisfy the functioning demands of the inkjet printer.

Combining expertise with technology

Chuntian Technology has amassed extensive project expertise in inkjet printer manufacture over many years as a manufacturing backer behind intelligent industrial equipment. Using sophisticated CNC bending equipment, Chuntian precisely controls the bending angle and pressure in the sheet metal bending process, thereby lowering mistakes and raising processing accuracy. Our engineering team actively maximizes the process flow in design of processing flow, provides exact fixtures for positioning and processing, and guarantees the great uniformity of every workpiece.

Lean manufacturing helps thin plate processing.

Lean production depends on detecting the reason and fixing the simple distortion in stainless steel thin plate manufacturing in time. By means of reasonable mold design and operation techniques, Chuntian Technology lowers the incidence of internal stress and rebound during processing, thus assuring that the deformation of the material is essentially under control in important processes such bending and stamped. This is the outcome of constant processing parameter and technology optimization by our technical staff; it is also one of Chuntian Technology's strongest suit.