Sheet metal customized auto parts rely on bending for precise shaping, punching for weight reduction and connection. It can be customized according to car needs and has good adaptability. Strictly control quality, advanced and reliable technology, help cars drive stably and safely, and are favored in the field of auto parts for their advantages.

Auto Parts

Hot products

Product details description

In the vast field of auto parts, sheet metal custom processing products stand out and become indispensable with their unique craftsmanship charm and excellent performance.

Sheet metal custom processing has opened the journey of creating auto parts with its professionalism. We carefully select high-quality metal sheets as raw materials. These sheets have good strength, toughness and plasticity, laying a solid foundation for subsequent fine processing.

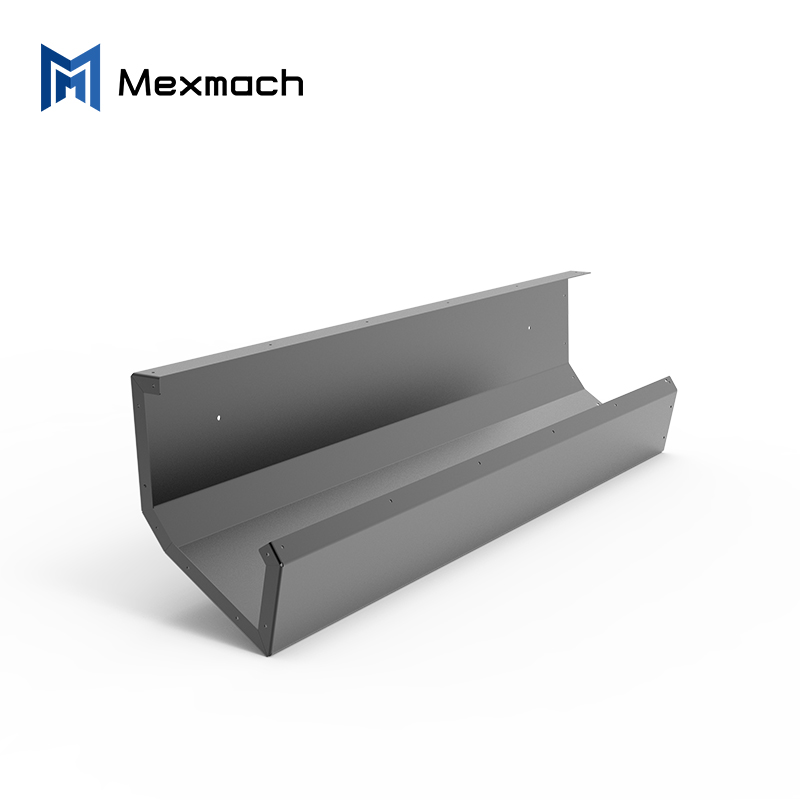

The bending process is undoubtedly the key link that makes sheet metal custom processing shine. With the help of advanced and high-precision bending equipment, experienced technicians can accurately bend metal sheets into various angles according to the specific design requirements of different cars, whether it is complex curve shapes or regular right-angle bends, they can be perfectly presented. This allows accessories to accurately adapt to the unique structures of various parts inside the car, whether it is the compact space of the engine compartment or the specific joints of the body frame, they can be seamlessly embedded, greatly enhancing the overall stability and coordination.

The punching process also plays a role that cannot be underestimated. By punching the accessories, evenly and reasonably distributed holes are born. On the one hand, these holes help to reduce the weight of the accessories themselves, which is in line with the current trend of lightweight automobiles, thereby improving fuel economy; on the other hand, they also provide convenient fixed points for subsequent connection and assembly with other parts, making the automobile assembly process more efficient and smooth.

Throughout the entire sheet metal custom processing process, from the strict screening of raw materials to the fine control of each process, to the strict quality inspection of the finished product, we adhere to the attitude of excellence to ensure that every sheet metal custom processing of automotive accessories can meet high standards and high quality, contribute to the safe driving, stable performance and long-term durability of the car, and is a trustworthy and high-quality choice for the automotive manufacturing industry.