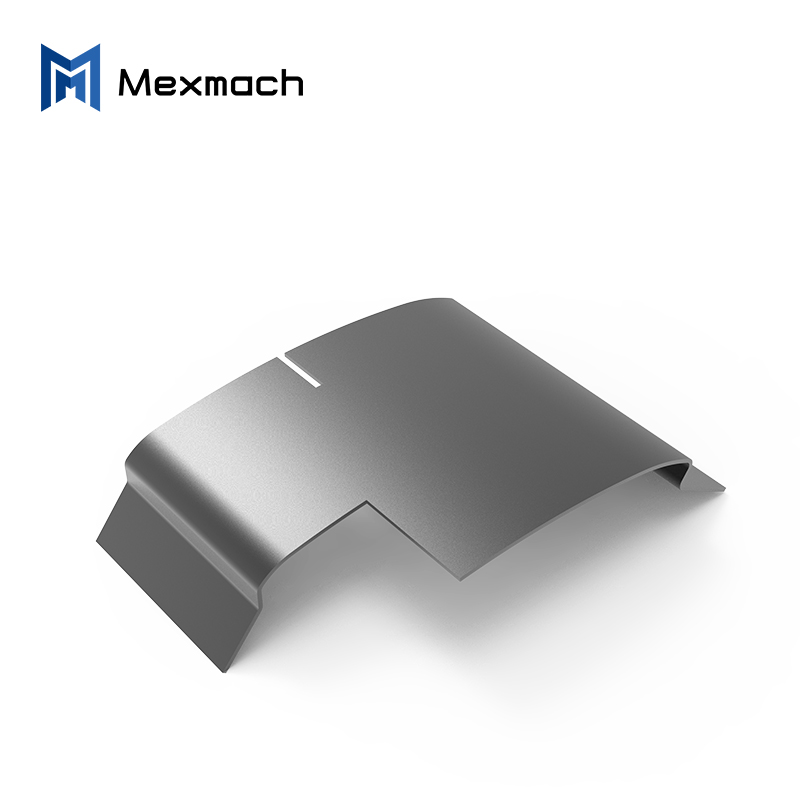

Sheet metal shell customized auto parts, relying on bending technology to shape accurately, punching technology to optimize function. Customized according to car needs, beautiful and practical. Strictly control quality, good adaptability, help cars show personality, in the customization of auto parts, it is favored by car owners for its advantages.

Auto Parts

Hot products

Product details description

In the diverse world of auto parts, sheet metal shell custom processing products are exuding a unique charm. It uses professional sheet metal processing methods, combined with key processes such as bending and punching, to tailor high-quality shell accessories that are both functional and aesthetic for cars.

When we start the customization journey, we will first strictly screen the raw materials and only use high-quality metal sheets with uniform texture and high strength, which can withstand the test of various complex environments. This lays a solid foundation for creating durable sheet metal shells.

The bending process plays a decisive role in shaping the shell form. With the help of advanced CNC bending equipment and an experienced technical team, metal sheets can be accurately bent into various required shapes and angles. Whether it is to create rounded and smooth body panels or angular functional shell parts, the bending process can ensure that every bend is tight and accurate, so that the shell fits perfectly with the overall structure of the car, which not only improves the overall beauty of the car, but also enhances its aerodynamic performance.

The punching process also has irreplaceable value. Through careful planning and precise operation, the holes punched on the sheet metal shell are cleverly arranged. On the one hand, these holes help optimize the heat dissipation function of the shell, ensuring that the relevant equipment inside the car can dissipate heat in time during operation and maintain a good working condition; on the other hand, it also provides convenient fixed points for the subsequent installation of various external devices, decorative elements, etc., making the personalized customization of the car easier and more convenient.

The entire sheet metal shell customization process follows a strict quality control system. From the pretreatment of the sheet to the fine polishing of the finished product, every link is controlled by a dedicated person, striving to make every customized sheet metal shell become a refined "outerwear" of the car, contributing to the quality improvement and unique charm of the car, and is a reliable choice in the field of customized auto parts.