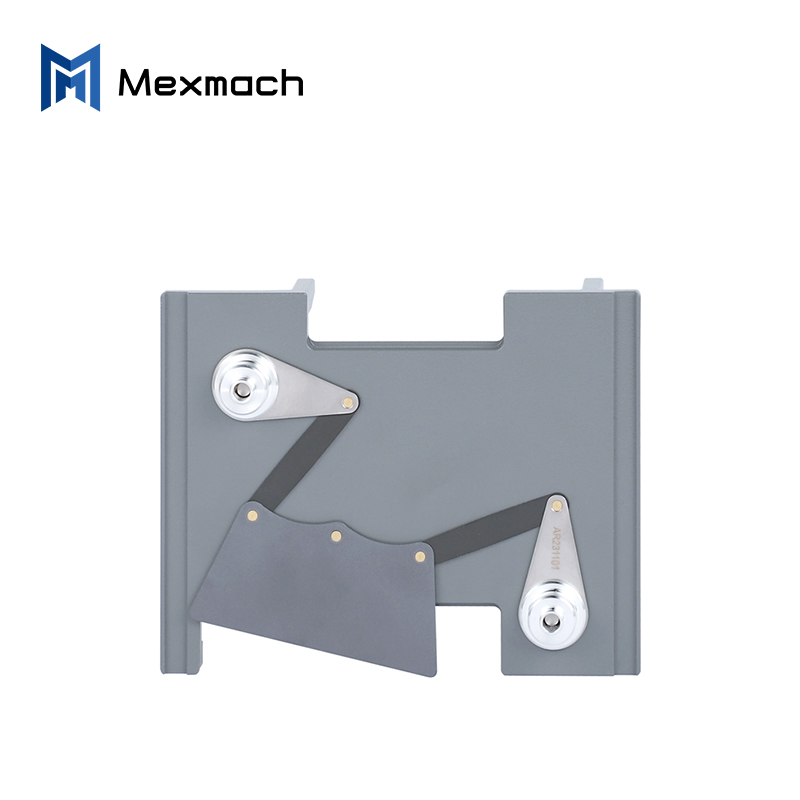

The mechanical frame blade assembly is created by CNC and other processes, etching and carving, lathe shaping, polytetrafluoroethylene to improve performance, and nickel plating to increase hardness. Strict quality control, good adaptability, can be used in multiple industrial scenarios, and is highly recognized in the industry for its high quality and excellent performance.

lighting

Hot products

Product details description

As an important industrial product, the mechanical frame blade assembly has demonstrated excellent performance and reliable quality after being manufactured through professional CNC processing, etching processing, lathe processing and other sophisticated processes, and plays a key role in many application scenarios.

We use high-quality raw materials to start the production journey to ensure that they have good basic performance. During the processing, etching processing is like a fine "sculptor", which can accurately etch the required texture, pattern or tiny structure on the surface of the component, laying the foundation for the realization of subsequent functions, so that every detail meets strict design requirements.

Lathe processing relies on its high-precision rotary cutting to gradually shape the raw materials into a shape that meets the specifications. Whether it is the roundness and smoothness of the shaft part or the regular contour of the frame, it can be achieved through lathe processing. Ideal state, ensuring the accuracy and stability of the basic form of the product.

And CNC processing is the core link of the entire manufacturing. It accurately controls the tool path through a pre-set program to achieve the perfect creation of complex shapes and high-precision dimensions. Whether it is the unique curved shape of the blade or the fine connection structure inside the frame, CNC processing can accurately present it, so that all parts fit together seamlessly.

The use of polytetrafluoroethylene technology gives the product excellent corrosion resistance and low friction characteristics, allowing it to run smoothly in complex environments; the nickel plating process enhances the surface hardness and aesthetics of the product, making it more durable and eye-catching; the use of MOLYKOTE further optimizes the lubrication performance of the product, reduces wear and extends its service life.

From raw materials to finished products, every process is under strict quality control, and professionals conduct layer-by-layer inspections to create a mechanical frame blade assembly that meets high standards, meets the diverse use needs of the industrial field, and becomes a trusted and high-quality choice.