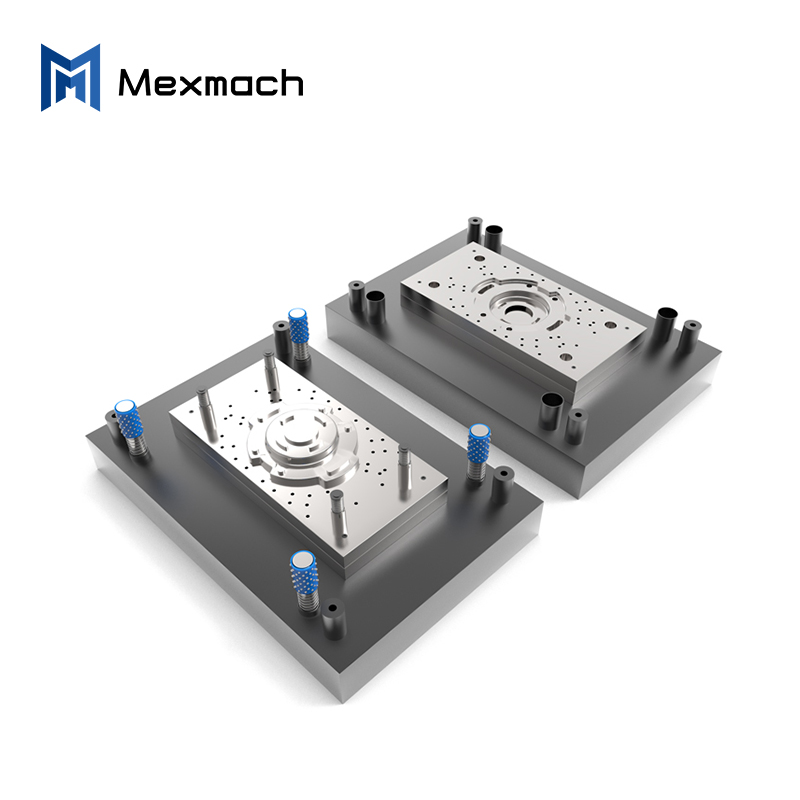

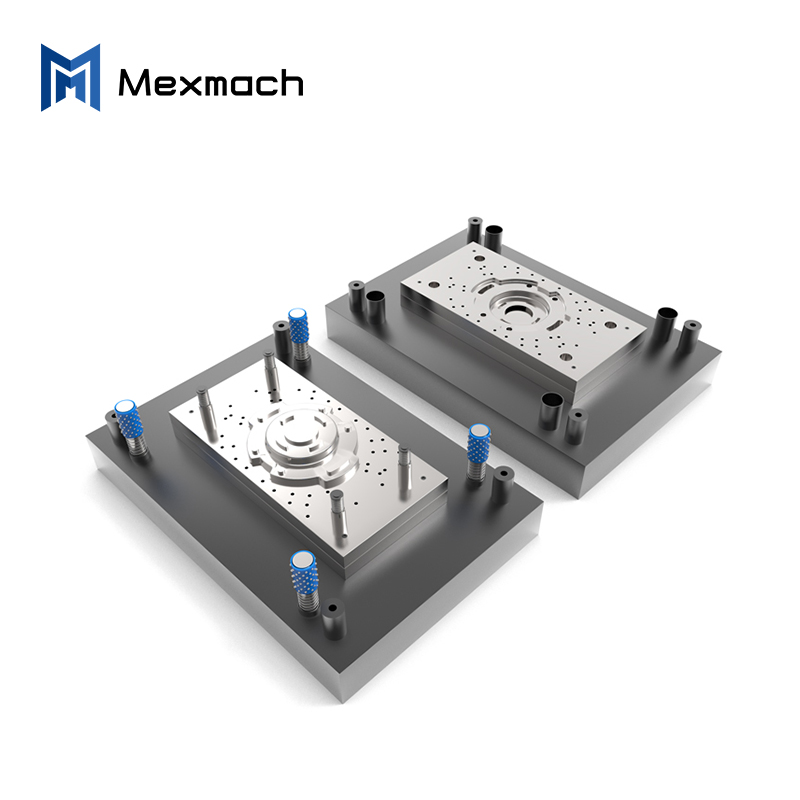

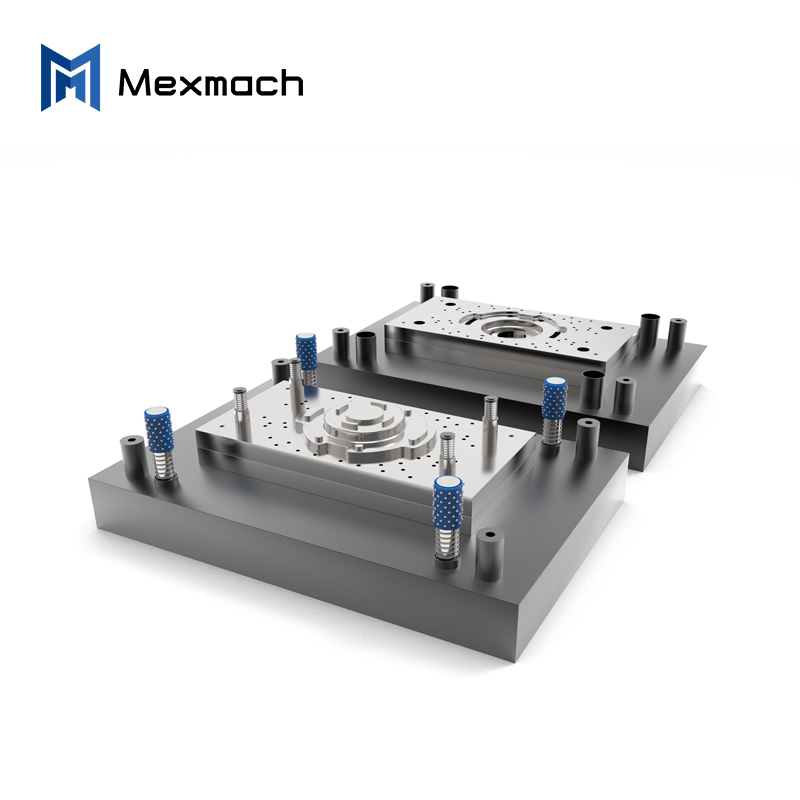

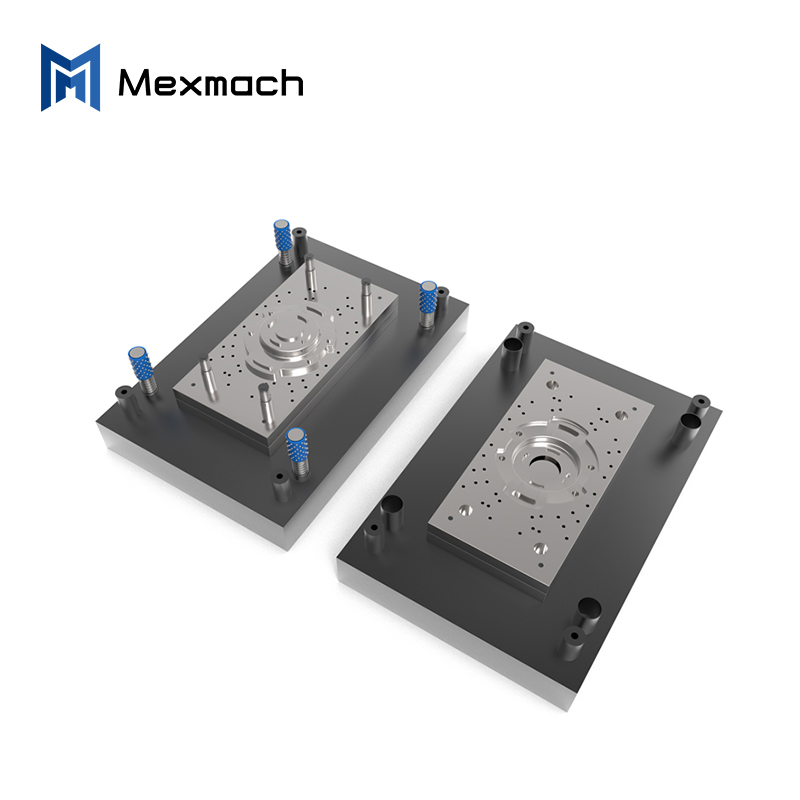

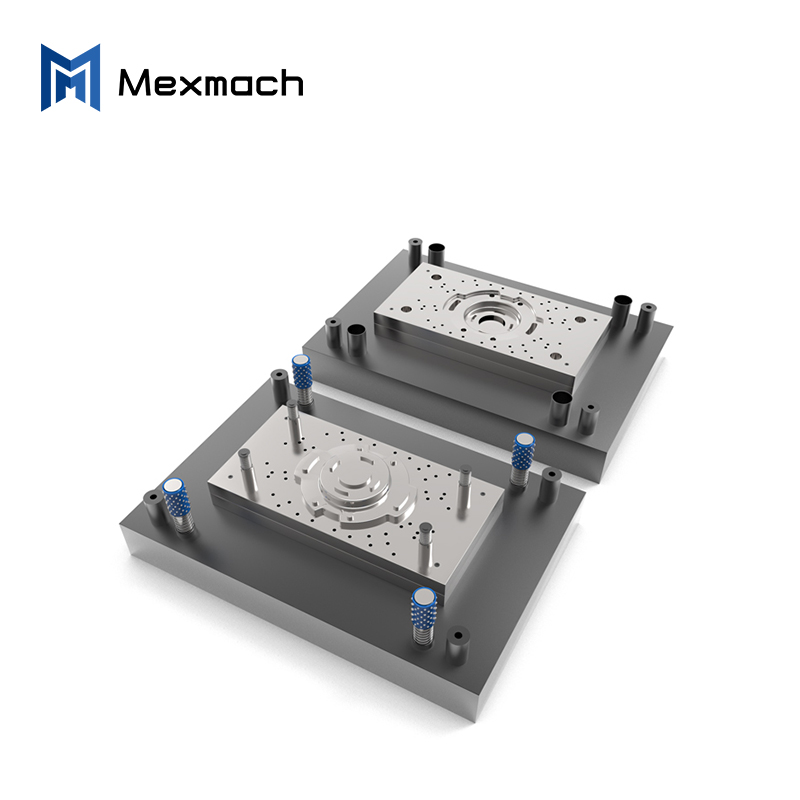

Metal stamping die is the key to metal processing. In the automotive, electronics and other industries, it relies on forming, precision guarantee, efficiency improvement and material utilization optimization to stamp metal sheets into precise shapes, ensure product quality, improve production efficiency, and promote the development of the metal processing and manufacturing industry.

Intelligent Industry

Hot products

Product details description

Metal stamping dies are the core process equipment in the field of metal processing. In the automobile manufacturing industry, it undertakes the key task of stamping metal sheets into body structural parts, engine parts, etc. For example, car doors, hoods and other body covering parts can quickly obtain precise shapes and sizes through the strong stamping of stamping dies. Its efficient forming ability greatly improves the efficiency of automobile production, while ensuring the consistency and high strength of various parts of the body, meeting the dual needs of automobile safety and beauty.

In the production of electronic equipment, metal stamping dies also play an indispensable role. Like the metal frame of the mobile phone, the internal metal bracket of the computer, etc., are all stamped by stamping dies. It can process metal sheets into various complex shapes, meet the requirements of electronic products for miniaturization, lightweight and precision, and provide strong support for the high performance and portability of electronic equipment. The main role of metal stamping dies is reflected in many aspects.