Hole machining of thin metal plates: Technical points of precision first

Release time:2024-12-12 Click:93Regarding metal processing, metal sheet hole processing precision is really vital. High-precision holes may guarantee the exact installation and excellent functioning of components in sectors like aerospace, electronic equipment, or automotive manufacture.

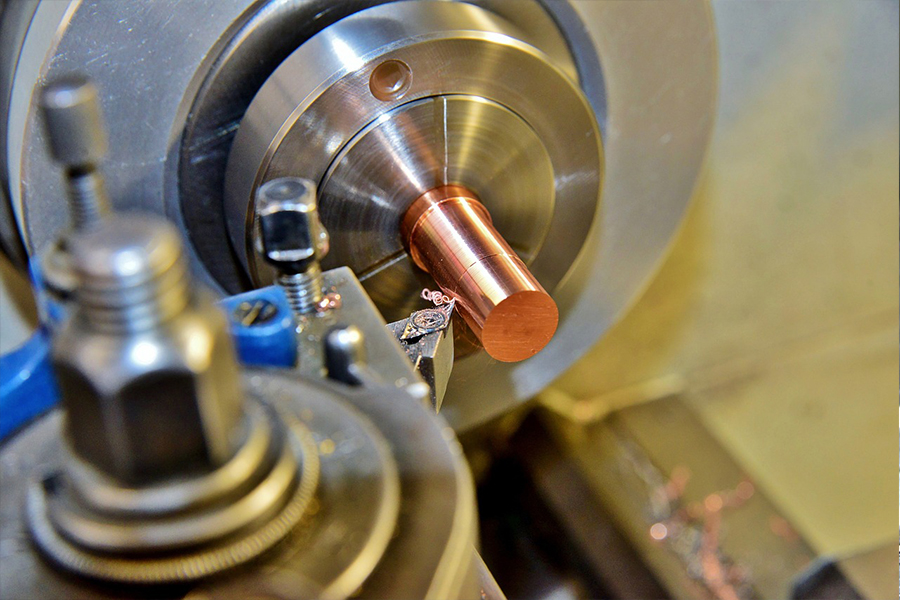

First of all, the secret is the instruments' choosing. Sharp and appropriate size drills or milling cutters should be used for metal sheet hole processing. Sharp tools may lower the cutting forces and lower the thin plate deformation potential. For instance, high-hardness, good-wear-resistant carbide drills guarantee precision and may increase processing capacity. Furthermore, the tool's modern geometry has to be meticulously created. For instance, specific grinding angles help to significantly reduce burr production and smooth the hole wall.

Second, one cannot overlook proper cutting parameters. Directly influencing the processing accuracy of holes are cutting speed, feed rate, and cutting depth. Usually, lower feed rates and faster cutting speeds are used while processing metal sheets. While lower feed rates can better manage cutting thickness and minimize deformation of thin plates or out-of-tolerance hole sizes owing to too strong cutting pressures, higher cutting speeds aid to rapidly remove materials and limit the influence of heat buildup on thin plates.

Ensuring precision also depends much on the clamping technique. Appropriate clamping tools are needed as metal sheets are readily deformed. To prevent too strong local force, a vacuum adsorption device may attach the sheet uniformly; alternatively, a multi-point placement and elastic clamping fixture can guarantee the stability of the sheet while allowing a certain deformation gap. Once the procedure is finished, the sheet may be rebuilt to its original form, therefore guaranteeing the hole's precision. For instance, precision elastic fixture clamping efficiently prevents the metal shell of a mobile phone from deforming, therefore guaranteeing the accuracy of the hole location while processing small holes on it.

First, accuracy requires linkages of cooling and lubrication as well. Cutting during the metal sheet hole operation will produce a lot of heat. Should the heat unable to be removed in time, the sheet would undergo thermal deformation and tool wear will rise. Appropriate cooling lubricants, like emulsions or cutting oils, may not only lower the cutting temperature but also minimize the friction between the tool and the sheet, thereby improving the surface quality of the hole. For instance, constant supply of cutting oil may help to lower the surface roughness of holes drilled in stainless steel sheets and simplify dimensional accuracy management.

Furthermore very crucial is the improvement of the processing technology. Drilling first then reaming or boring may be a procedure combination employed for specific holes requiring great accuracy. Initially created is drilling; reaming or boring helps the hole's surface quality and precision even more. Simultaneously, the use of sophisticated CNC machining technology can precisely manage parameters such hole location, diameter and depth and properly regulate the movement trajectory of the tool. For instance, the multi-axis linkage CNC machining center combined with the ideal process guarantees the very high precision requirements of the cooling holes and satisfies the needs of effective heat dissipation and stable engine operation in the processing of cooling holes on aircraft engine blades.

Comprehensive consideration and strict control of the technical points from several angles—such as tool selection, cutting parameter setting, clamping method, cooling lubrication and processing technology optimization—is essential to attain the highest accuracy in the processing of metal sheet holes. Only in this manner can high-precision holes meeting the demands of different high-end manufacturing sectors be handled on metal sheets, thereby advancing linked industry technical development and product quality enhancement.