Texture shaping: Secrets to the aesthetic upgrade of metal sheets

Release time:2024-12-14 Click:94Modern manufacturing and design are fields where the use of metal sheets is become progressively widespread. From architectural ornamentation to electronic device housing, from furniture design to automotive manufacture, metal sheets have become the ideal material in many disciplines with their special performance and elegant look. Texture shaping is a key secret to get aesthetic improvements in the processing of metal sheets.

Although the metal sheet itself has a certain sheen and texture, without texture it usually seems boring and inadequate. Unique visual effects and touch may be applied to the metal sheet by means of texture shaping, therefore augmenting its beauty and individuality. Simultaneously, the texture may also be anti-slip, wear-resistant, anti-fingerprint, etc., thus enhancing the usefulness of the metal sheet.

Approach of texture sculpting

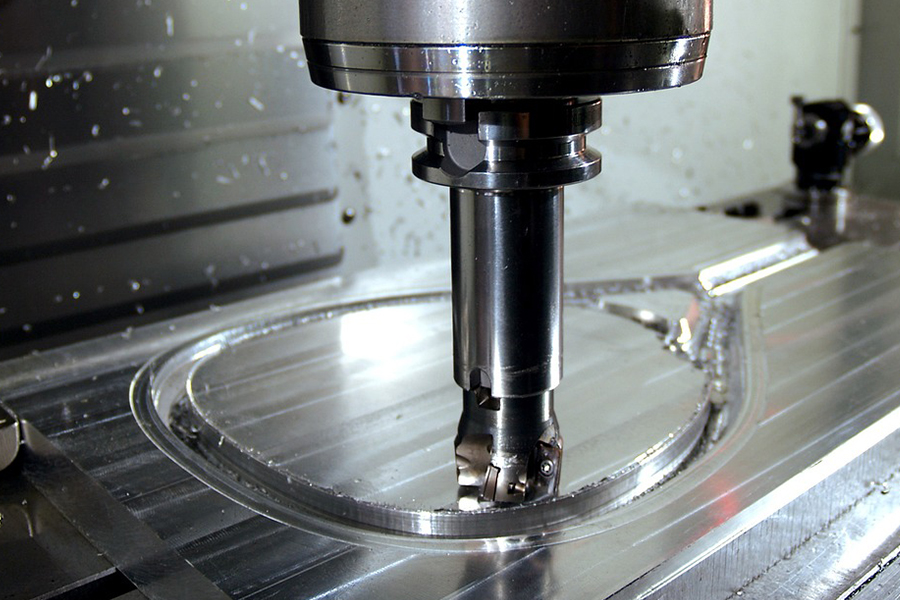

One of the most often used technique for texture sculpting is mechanical processing. Different textures may be handled on the surface of metal sheets by means of different tools and processing procedures; they include straight lines, diagonal lines, grid lines, corrugations, etc.? Low processing efficiency and great expense are the drawbacks of mechanical processing; the benefits include great processing precision, crisp texture, and strong repeatability.

Chemical etching is a technique for surface pattern development on metal sheets by use of chemical solutions corroding them. In order to provide the metal sheet a richer color effect, chemical etching may also accomplish color etching and make extremely fine textures like hairline and frosted textures. Chemical etching has minimal cost, great processing efficiency, and can produce intricate texture pattern; its downside is that it somewhat contaminate the surroundings.

Laser engraving is the technique wherein metal sheets are processed using laser beams to produce surface textures. In order to give the metal sheet a more three-dimensional visual impact, laser engraving may create very fine textures including lettering, patterns, QR codes, etc.; it can also accomplish three-dimensional engraving. While quick speed, great processing precision, and minimal pollution define the benefits of laser engraving, expensive equipment cost is a drawback.

Using molds to extrude metal sheets to create surfaces with textures is known as embossing. Strong three-dimensional sensation may be produced by embossing technique from patterns, leather grains, wood grains, etc., and also from concave and convex effects. Although the embossing method has cheap cost, great processing efficiency, and can be used for large-scale manufacture, its downside is great mold creation cost.

Important ideas guiding texture determining design

Match with product style: To get the impression of aesthetic improvement, texture shaping should be designed in line with the general style of the good. For contemporary minimalist style items, for instance, you may pick simple, smooth, straight lines or diagonal lines; for retro style products, you could use carved patterns or antique designs with a feeling of history.

Practicality should be taken into account when designing texture shaping; it should be not simply gorgeous. For items that need non-slip, for instance, you may pick a texture with an anti-slip effect; for products that demand anti-fingerprint, you can choose a texture with an anti-fingerprint effect.

Pay close attention to the texture's scale and proportion; they should be well planned depending on the size and use of the product. The beauty and usefulness of the product might suffer if the scale is too tiny or the texture percentage is too great.

Try creative design: To produce a more distinctive visual impact in the texture shaping design, consider creative design. You may mix many textures, for instance, or blend textures with color and pattern aspects.

A key to get aesthetic improvements in metal sheet processing is texture shaping. Metal sheets are more appealing in many different sectors when their texture shaping techniques and design points are chosen correctly, thereby providing a more distinctive visual effect and touch.